Pump casting manufacturer

Looking for Reliable Pump Casting Solutions? Chongqing Sipx Machinery operates a dedicated casting foundry in China, specializing in the production of high-quality pump casting components. We offer comprehensive service from design consultation to precision manufacturing, ensuring prompt quotations and efficient delivery for your pump casting needs. Our expertise covers a wide range of pump types including housings, impellers, volutes, and diffusers.

Pump casting manufacturing is the essential process of creating critical pump components through various casting techniques, primarily sand casting and investment casting. Molten metal – such as ductile iron, gray iron, stainless steel, or specialized alloys – is poured into precisely engineered molds to form complex shapes like casings, impellers, and wear plates. As an experienced manufacturer and supplier, we utilize this process to produce durable parts capable of withstanding demanding operational environments, including high pressures, corrosive fluids, abrasion, and extreme temperatures. Our pump castings are integral to applications across vital sectors such as water supply and wastewater treatment, chemical processing, oil & gas, power generation, and industrial fluid handling, delivering critical performance and longevity.

pump shell casting

pump shell casting with coating

pump casting parts

sand casting gray iron pump shell

automotive clutch pump castings

casting vertical fire pump parts

Different casting methods used for pump casting

Multiple casting techniques are employed in pump casting production, with sand casting, investment casting, and die casting being the most prevalent methods utilized by industrial foundry operations.

Sand casting remains the most widely adopted pump casting method globally. This process involves creating intricate molds from specialized sand mixtures, into which molten metal is precisely poured. Investment casting (also called lost-wax casting) delivers exceptional dimensional accuracy for complex pump components: a wax prototype is coated with refractory ceramic material, then heated to melt the wax, leaving a hollow ceramic mold for metal casting. High-pressure die casting forces molten metal under significant pressure into reusable steel dies, enabling rapid production of consistent pump parts.

The optimal pump casting technique is determined by component specifications including geometry, dimensional tolerances, production volume, and material requirements. As a China-based supplier, Chongqing Sipx Machinery produces pump castings in diverse metallurgical options including ductile iron casting, carbon steel casting, corrosion-resistant alloys, aluminum, and bronze – selected according to hydraulic performance needs, fluid compatibility, and operational pressures. Every pump casting undergoes rigorous quality validation throughout our manufacturing process to guarantee reliable performance in demanding industrial service environments such as chemical processing plants, offshore platforms, and municipal water systems.

Types of materials used for pump casting manufacturer

Pump casting requires materials with high strength, corrosion resistance, and good wear resistance. The selection of materials for Pump casting depends on the application, operating conditions, and the fluid or gas being handled. Some of the commonly used materials for pump casting include:

|

Materials |

Detail |

|

Alloy Steel |

Alloy Steel is a popular material choice for pump castings due to its strength and durability. It is also resistant to corrosion and can withstand high temperatures |

|

Stainless Steel |

Stainless steel is a popular material choice for pump castings, especially in applications where corrosion resistance is important. It is also strong and durable, and has good fluid-carrying capabilities. |

|

Aluminum |

Aluminum is lightweight, and it offers good corrosion resistance and thermal conductivity. It is often used for pumps that handle water and other low-viscosity fluids. |

|

Cast iron |

Cast iron is a durable material that is commonly used for pump castings. It is strong, resistant to wear and tear, and has good fluid-carrying capabilities. |

|

Brass |

Brass is a non-ferrous metal that is widely used for pump castings. It is corrosion-resistant, has good fluid-carrying capabilities, and is easy to machine. |

|

Bronze |

Bronze is a strong and durable material that is often used for pump impellers and casings. It is resistant to corrosion and wear, and can withstand high temperatures. |

Post processes after pump casting

Following the initial pump casting production phase, multiple post-processing stages are essential to transform raw castings into functional, high-performance components. As an experienced foundry and supplier in China, Chongqing Sipx Machinery implements comprehensive post-casting procedures tailored to meet demanding hydraulic application requirements.

Critical post-processes for pump castings include:

-

Heat Treatment: Strategic thermal processing (such as annealing or quenching) enhances metallurgical properties including tensile strength, impact resistance, and hardness. This controlled heating/cooling cycle optimizes microstructure while improving corrosion and wear resistance – crucial for extended service life in abrasive or chemically aggressive fluids.

-

Precision Machining: CNC turning, milling, drilling, and grinding operations achieve critical dimensional tolerances and sealing surface finishes. This ensures proper fitment with shafts, bearings, and housings while maintaining hydraulic efficiency.

-

Surface Preparation: Techniques like shot blasting, vibratory finishing, or electrochemical cleaning remove scale and oxidation, creating optimal substrate adhesion for protective coatings or plating essential for corrosion prevention.

-

Non-Destructive Testing (NDT): Advanced inspection via radiographic (X-ray), ultrasonic, magnetic particle, or dye penetrant methods verifies structural integrity, detecting subsurface flaws, porosity, or inclusions that could compromise pressure containment.

-

Component Assembly: Integration with rotating elements, seals, and fasteners transforms individual pump castings into operational sub-assemblies, ready for final system integration.

-

Rigorous Quality Validation: Dimensional audits, pressure testing (hydrostatic/pneumatic), material certification, and performance simulation guarantee compliance with international standards (ISO, ASTM, API), ensuring reliability across industrial pumping applications.

Different industries that use pump castings

Pump castings serve as critical components across diverse industrial sectors, enabling efficient fluid handling in demanding operating environments. As a specialized foundry and supplier based in China, Chongqing Sipx Machinery manufactures precision pump castings engineered to meet rigorous application requirements worldwide.

Key industries utilizing our pump casting solutions include:

-

Agriculture: Irrigation systems, livestock water supply, and drainage pumps requiring corrosion-resistant housings and impellers.

-

Chemical Processing: Acid transfer, solvent circulation, and reactor feed pumps demanding alloy castings with exceptional chemical compatibility.

-

Oil & Gas: Upstream extraction, pipeline boosting, and refinery process pumps operating under extreme pressures/temperatures.

-

Water Infrastructure: Raw water intake, filtration systems, and wastewater treatment plants utilizing high-volume pump castings.

-

Mining & Minerals: Slurry transfer, dewatering, and tailings management pumps handling abrasive media with specialized wear components.

-

Food & Beverage: Hygienic process pumps featuring polished surfaces and compliant metallurgy for product integrity.

-

Pharmaceutical: Precision metering and sterile transfer pumps requiring validated material traceability.

-

Marine Engineering: Ballast systems, bilge pumps, and offshore processing units exposed to saline environments.

-

Construction: High-pressure concrete pumping and site dewatering equipment with robust hydraulic components.

-

Power Generation: Cooling water circulation, fuel oil transfer, and FGD system pumps in thermal/nuclear plants.

This extensive applicability demonstrates how pump casting technology delivers essential fluid control capabilities. Our manufacturing expertise ensures these critical components maintain operational reliability across varying temperatures, pressures, and corrosive media – meeting global standards for severe-service industrial applications.

Investment casting process for pump body

A wax model of the pump body was successfully produced by assembling a water-soluble core and wax model for pump body castings with large external dimensions and complex shapes. The pump body casting was successfully cast by using silica sol technology for shell making, designing a reasonable pouring system, determining a reasonable dewaxing process and pouring process.

Pump products are widely used to transport various fluids. To ensure performance, high requirements are  placed on the dimensional accuracy and surface bar longitude of the inner wall flow channel of the pump body, as well as the pressure value and appearance quality of the pump body itself. Due to the limitations of its process characteristics, investment casting generally has a casting weight of only a few grams to a few kilograms. For castings with large dimensions and complex shapes, there are certain difficulties in both pressing wax molds and shell making processes.

placed on the dimensional accuracy and surface bar longitude of the inner wall flow channel of the pump body, as well as the pressure value and appearance quality of the pump body itself. Due to the limitations of its process characteristics, investment casting generally has a casting weight of only a few grams to a few kilograms. For castings with large dimensions and complex shapes, there are certain difficulties in both pressing wax molds and shell making processes.

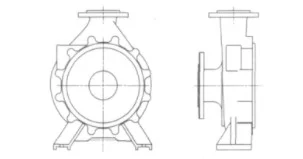

Example: A batch of pump bodies (casting blanks) with an external dimension of 515mm × 410 mm, with a mass of 47.85 kg, made of CF8M material, as shown in Figure 1. After careful design and adopting a reasonable process plan, this batch of pump body castings has been successfully produced.

1、 Wax mold production

1.1 Production of urea core

Due to the structural characteristics of the pump body itself, it is impossible to directly press out the inner cavity of the pump body from the mold. According to the actual production, the urea core process is adopted. As the dimensional accuracy and surface roughness of the pump body flow channel are all determined by the urea core, the production requirements of the urea core are strict. Urea and white sugar are mixed in a (mass ratio) of 100:5 and heated to 130-150 ℃. After melting, they are poured into a model with evenly coated turpentine in the inner cavity. After complete cooling, the urea core is taken out for inspection. The urea core is required to be white, with a smooth and defect free surface, and the size is qualified.

1.2 Precision Wax Pattern Production

For pump casting components requiring investment casting, wax pattern fabrication follows strict thermal parameters: injection temperatures maintained at 54-60°C with controlled pressure of 0.8-1.0 MPa. Cycle times include 50-second injection phases followed by 10-minute stabilization periods to ensure dimensional stability. Large flange plates undergo individual wax injection and subsequent welding to main patterns, guaranteeing structural integrity. Final wax patterns must exhibit flawless surface finish on both external and internal cavities, free from flow marks or imperfections. Critical geometric requirements include perpendicular orientation between the major flange and base plane, with parallel alignment maintained across all 12 counterbores on the opposing face. Precision reshaping is performed when necessary to meet these exacting pump casting specifications.

1.3 Optimized Gating System Design

Given the pump casting’s end-use requirement for pressure integrity testing (mandating zero shrinkage or porosity defects), targeted feeding solutions address thermal challenges. The 12 frontal protrusions and discharge nozzle roots are identified as critical hot spots through solidification simulation. To counteract potential shrinkage, strategically positioned feeder risers are incorporated above these high-mass sections. Our foundry in China developed two distinct gating system configurations – Scheme A utilizing top-gating with multiple downsprue for directional solidification control, and Scheme B employing bottom-fill with vortex runners for reduced turbulence – both engineered to enhance metallurgical soundness while accommodating this complex pump casting geometry. Final selection depends on casting orientation analysis and mold filling studies.

(1) Option 1 injection method is riser top injection

Adopting a cross shaped die head with assembly

welding, the length is determined by the casting, the width of the runner is 55mm, the thickness of the runner is 50mm, and the size of the flow cup is Φ 30 mm x Φ 90mm × 180 mm.

(2) Option 2 injection method is joint injection

On the basis of Scheme 1, add one side of the sprue and sprue cup at the bottom of the pump body, and connect it to the bottom flange.

2、 Shell making

To ensure the strength of the shell and the surface roughness of the casting, the silica sol process is adopted. The specific process parameters are shown in Tables 1 and 2.

Due to the large volume and uneven wall thickness of the casting, if ordinary dewaxing methods are used for dewaxing, the shell may experience bulging and cracking due to uneven heating. Therefore, it is necessary to improve the dewaxing process to achieve sequential dewaxing.

The specific method is to wrap the pump body shell with three layers of waste newspaper, exposing the riser and runner. This way, the wax mold of the pouring system is melted and flows out first, forming a channel for the flow out of the pump body wax mold, thereby achieving sequential dewaxing. The dewaxing pressure is 0.6-0.75 MPa, the dewaxing time is 25-30 minutes, and the shell condition is good after dewaxing.

| Table 1 Coating Preparation | ||||

| Coating | Coating type | ratio of liquid to powder/s | Guan’s fluid viscosity | Note |

| 1-2 layer | Silica sol+zircon powder | 1:3.6 | 36土2 | Zircon powder with a particle size of 320 mesh |

| 3 layer | Silica sol+coal gangue powder | 1:(1.6-1.8) | 16-19 | The particle size of coal gangue powder is 30-60mesh |

| 4-7 layer | Silica sol+coal gangue powder | 1:(1.3-1.5) | 13-15 | The particle size of coal gangue powder is 16-30 mesh |

| sealing layer | Silica sol+coal gangue powder | 1:(1.1-1.2) | 12-18 | |

| Table 2 Shell making parameters | |||||

| Coating | Sanding type | drying temperature/centigrade | Humidity | drying time | Wind speed (a/s) |

| 1 layer | 100 mesh Zirconium sand | 24土2 | 50-70 | 8-9 | breezeless |

| 2 layer | 80 mesh mullite sand | 24土2 | 50-70 | 12-14 | breeze |

| 3 layer | 30-60 mesh coal gangue sand | 24土2 | 40-60 | 15-16 | 3-5 |

| 4-7 layer | 16-30mesh coal gangue sand | 24土2 | 30-50 | 16-18 | 6-8 |

| sealing layer | 24土2 | 30-50 | 24 | 6-8 | |

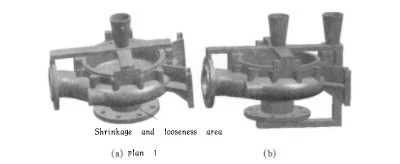

3、 Shell cultivation and casting

Due to the large volume of the mold shell and the thickness of the casting wall, in order to ensure the quality of the mold shell firing, the firing temperature should be appropriately increased and the insulation time should be extended. The cultivation temperature used is 1080-1100 ℃, and the cultivation time is 1 hour. After adopting scheme 1 for pouring, severe shrinkage and porosity occurred at the hot joint at the root of the casting outlet. The casting quality produced by using Plan 2 is good.

The specific pouring process is as follows: first, use a side gate cup to pour the molten steel to 2/3 of the entire casting, and then use a middle flow cup to fill the molten steel. The shell temperature is greater than 950 ℃, the molten steel pouring temperature is 1620-1630 ℃, and the pouring time is 120 seconds. To prevent shrinkage and loosening, add molten steel and cover the riser with insulation agent within 30 seconds after pouring. During the cooling process of the casting, local water quenching is carried out at the hot joint at the root of the protrusion and outlet.

By designing a reasonable wax mold production process and shell making process, a larger pump body shell can be manufactured. The method of sequential dewaxing was adopted to effectively prevent bulging and cracking of the mold shell. The improved pouring system scheme was adopted, and after cleaning the castings, there were no shrinkage holes or looseness, and there was no obvious deformation. After inspection, the surface quality met the user’s requirements, the size was qualified, and the air pressure test was qualified.

FAQ

Pump casting manufacturing is the process of creating metal castings to build pumps, which are used to move fluids, such as water, oil, and gas, from one place to another.

Common materials used include iron, steel, aluminum, brass, and bronze.

The advantages of pump casting manufacturing are its efficiency, ease of production, customization, and cost effectiveness.

Choose a pump casting manufacturer with extensive experience, knowledge, equipment, and resources to meet your specific requirements. It is also important to check their quality standards, certifications, and customer feedback.

The lead time for pump casting manufacture depends on several factors, such as the complexity of the design, material availability, production capacity, and finishing requirements. It usually takes a few weeks to a few months.

Pumps for various applications, such as centrifugal pumps, diaphragm pumps, gear pumps, metering pumps, plunger pumps, and submersible pumps can be manufactured through pump casting.

The steps involved include designing the casting mold, melting the metal, pouring the molten metal into the mold, allowing it to cool and solidify, demolding, finishing, and testing.

The production capacity of our precision casting foundry can produce 50000pcs per month.

We meet the ISO8062(GB/T6414) CT4-CT8 of Nominal dimension (mm) Linear dimension tolerance

At SipxMach, our goal is to help our customers lower production costs and increase production rates and quality. Interested to see what SipxMach can do for you and your team? Contact us to schedule a tour of our state-of-the-art facility

- Contact: Rubio

- Email: [email protected]

- Microsoft Teams: Rubioli8677 (Sales manager)

- Office Add: No.551, Baosheng Avenue, Huixing Street, Yubei District, Chongqing, China

- Foundry Add: No. 4 Jindi Avenue, Dongcheng Street, Tongliang District, Chongqing