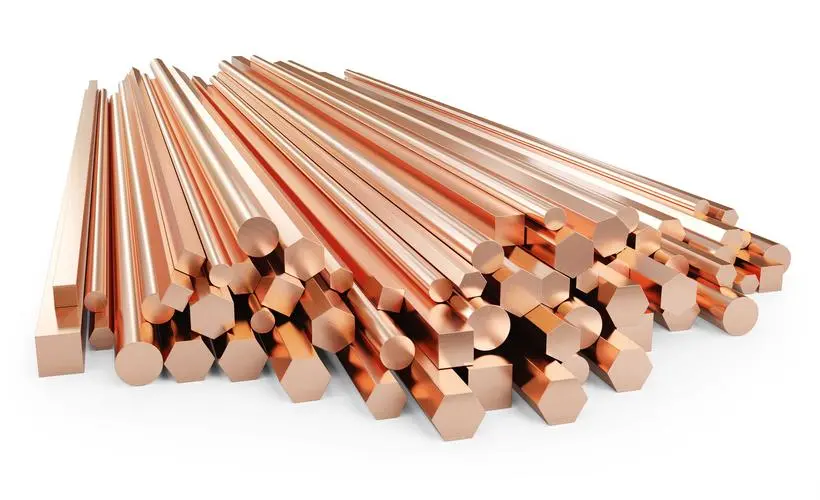

Copper Casting Manufacturer

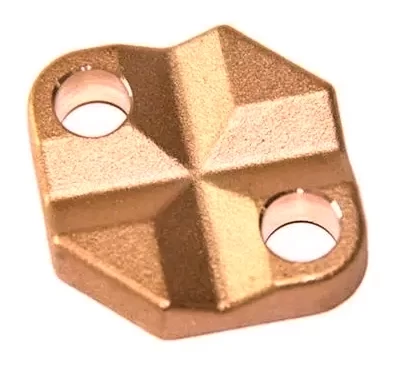

Cast copper, a versatile material that encompasses multiple alloys, is widely utilized across various industries due to its exceptional properties and ease of casting. Sourced from reputable suppliers and manufacturers in China, this metal is an ideal choice for a diverse range of applications, including pipeline fixing devices, ship propellers, power plant pump wheels, bushings, and bearing sleeves.

Its popularity stems from its unique characteristics that make it indispensable for manufacturing high-quality components. As a reliable material supplier, we at SIPX are committed to providing top-tier cast copper products and services to meet the specific needs of our clients, both domestically and internationally. Leveraging our advanced manufacturing capabilities and extensive experience, we ensure that each product meets the highest standards of quality and performance.