Metal Thailand 2024 Injects New Momentum to Asia Manufacturing Industry

Press Release, Image source: China Foundry Association (CFA)

On September 19, 2024, the 6th Asian Foundry Forum with the theme of “Gathering Industry Organizational Strength and Accurately Connecting Industrial Resources” was held at the Bangkok International Trade Exhibition Center in Thailand. Representatives of foundry industry organizations from China, Japan, India, Vietnam, Indonesia and other countries and regions, as well as domestic and foreign foundry industry guests, have gathered in Bangkok for the first time in five years to witness and participate in this grand event of the Asian foundry industry.

Casting, as the foundation of manufacturing, plays a crucial role in promoting industrial development. With the continuous advancement of technology and the increasing globalization of the market, the foundry industry is facing new opportunities and challenges. At the opening ceremony of the forum, Zhang Libo, Vice President of the China Machinery Industry Federation and President of the China Foundry Association, analyzed the current global economic situation and the development trend of the global manufacturing industry. He stated that as an important pillar of economic development, the level of development of the manufacturing industry directly affects the quality and competitiveness of the entire regional economy. “Faced with common challenges, we need to strengthen cooperation and work together to promote the sustained prosperity and development of the Asian foundry industry and downstream manufacturing industry.

The Asian foundry industry plays a pivotal role in the development of the world’s foundry industry, but at the same time, the development level and scale of the foundry industry vary greatly among Asian countries. Therefore, strengthening regional cooperation and promoting the industry to move towards a high-quality development track of green intelligence are urgent tasks. In his welcome speech, Wasunt Wongthanasunthorn, Vice President of the Thai Foundry Association, introduced Thailand’s unique advantages, the development of the manufacturing industry in recent years, and the market prospects to the attending representatives. He expressed sincere gratitude and honor for the Thailand exhibition and the Asian Foundry Forum held in Bangkok. He hopes that Asian countries can take this opportunity to strengthen cooperation and welcomes more enterprises to invest and develop in Thailand.

Hiroshi NISHIHARA, International Exchange Commissioner of the Japan Foundry Association, pointed out in his report “Current Status and Trends of Japan’s Foundry Industry” that due to the lightweight development of the automotive industry – shifting from internal combustion engine vehicles to hybrid or electric vehicles, the market share of cast iron in Japan will decrease from 2022 to 2023, while aluminum die castings will show significant growth.

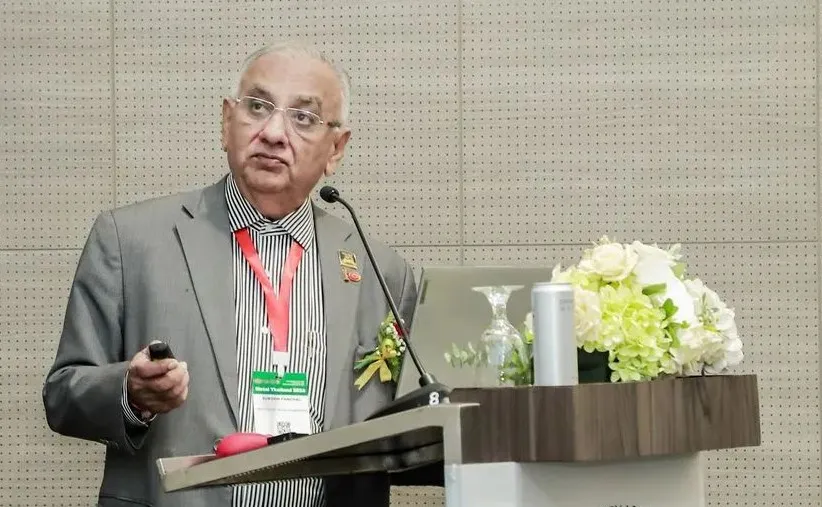

Subodh PANCHAL, former president of the Indian Foundry Industry Association, stated in the report “Current Status and Trends of India’s Foundry Industry” that India’s new manufacturing policy will increase the proportion of manufacturing in GDP from the current 15% to 25%, and create 100 million new jobs in the next 10 years. Due to the use of castings in all engineering and other departments, casting plays a crucial role in supporting the manufacturing industry, hence the need for sustainable development of the casting industry.

Subodh PANCHAL, former president of the Indian Foundry Industry Association, stated in the report “Current Status and Trends of India’s Foundry Industry” that India’s new manufacturing policy will increase the proportion of manufacturing in GDP from the current 15% to 25%, and create 100 million new jobs in the next 10 years. Due to the use of castings in all engineering and other departments, casting plays a crucial role in supporting the manufacturing industry, hence the need for sustainable development of the casting industry.

Cheng Chieh WU, representative of the Taiwan Foundry Industry Association, pointed out in the report “Sustainable Future of Casting” that with the gradual recovery of the global economy, especially the rise in consumer demand in major economies, the prospects for Taiwan’s foundry industry are relatively optimistic. With the help of high-performance computing and artificial intelligence technology, the competitiveness of Taiwan’s foundry industry will continue to grow, and foundry companies will continue to increase their investment in green energy and infrastructure.

Rudy RAMADHAN, representative of the Indonesian Foundry Association, emphasized in the report “Current Status and Sustainable Development of the Indonesian Foundry Industry” that the sustainable development of the foundry industry should focus on the impact of casting quality and delivery on products, and human resources will have a significant impact on product delivery and skill improvement. The foundry industry needs to reduce the use of resources and energy, as well as the generation of waste, pollution, and carbon emissions.

Munkhjargal Tsedev, President of the Mongolian Metallurgical Association, gave a report on the current situation, prospects, and development trends of the foundry industry in Mongolia. He analyzed the operation of the foundry and upstream and downstream industries in Mongolia, and proposed the need and willingness to strengthen external cooperation.

To Duy Phuong, Vice President of the Vietnam Foundry Metallurgy Association and President of the Hanoi Foundry Metallurgy Association, provided a detailed analysis of the current situation, prospects, and development potential of the Vietnamese foundry industry in his report “The Status and Development Trends of the Vietnamese Foundry Industry”. He stated that by adapting to international market demand, improving production efficiency, optimizing product quality, and actively participating in international cooperation, Vietnam’s foundry industry is expected to continue to maintain stable growth in the future.

To Duy Phuong, Vice President of the Vietnam Foundry Metallurgy Association and President of the Hanoi Foundry Metallurgy Association, provided a detailed analysis of the current situation, prospects, and development potential of the Vietnamese foundry industry in his report “The Status and Development Trends of the Vietnamese Foundry Industry”. He stated that by adapting to international market demand, improving production efficiency, optimizing product quality, and actively participating in international cooperation, Vietnam’s foundry industry is expected to continue to maintain stable growth in the future.

Zhang Zhiyong, Executive Vice President of the China Foundry Association, introduced the current situation and prospects of China’s foundry industry in his report “Development Status and Prospects of China’s Foundry Industry”, including the progress of the foundry industry, upstream and downstream industries, and the production capacity of some key castings. He described the development trend of China’s foundry industry, stating that lightweight, green and low-carbon, standardization, talent cultivation, and international cooperation have become key factors for the sustainable development of China’s foundry industry.

The ongoing thematic reports provide an efficient communication platform for industry colleagues with rich content and diverse perspectives. At present, factors such as weak global economic recovery, significant increase in operational risks and uncertainties, and continuous restructuring of international industrial and supply chains have posed challenges to the foundry industry. At the same time, new technologies, materials, processes, and products have brought new opportunities to the foundry industry. Against this backdrop, this forum has become a major platform for deep cooperation and innovative development in the Asian foundry industry, setting new milestones for the development of the Asian foundry industry, industry exchanges, and cooperation between technology and industry. In the future, we hope to continue to work together and promote exchanges and cooperation in the Asian foundry industry, injecting new impetus into the sustainable development of the foundry industry and creating a better future.