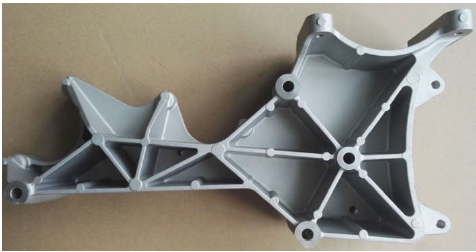

Aluminum Casting Foundry in China

Chongqing SIPX – Your Trusted Aluminum Casting Partner in China

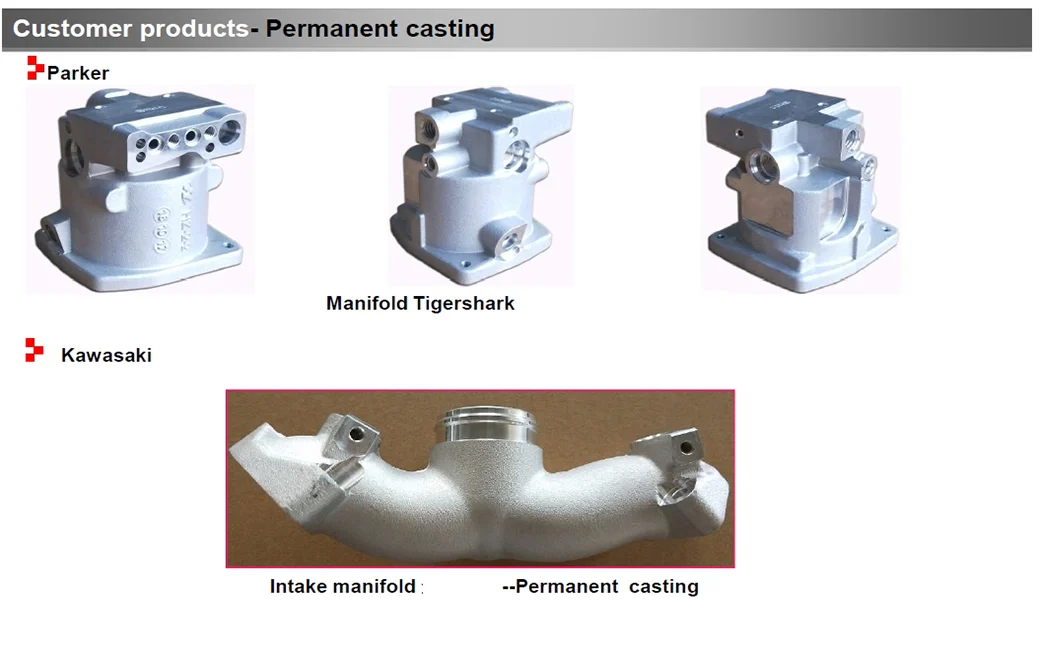

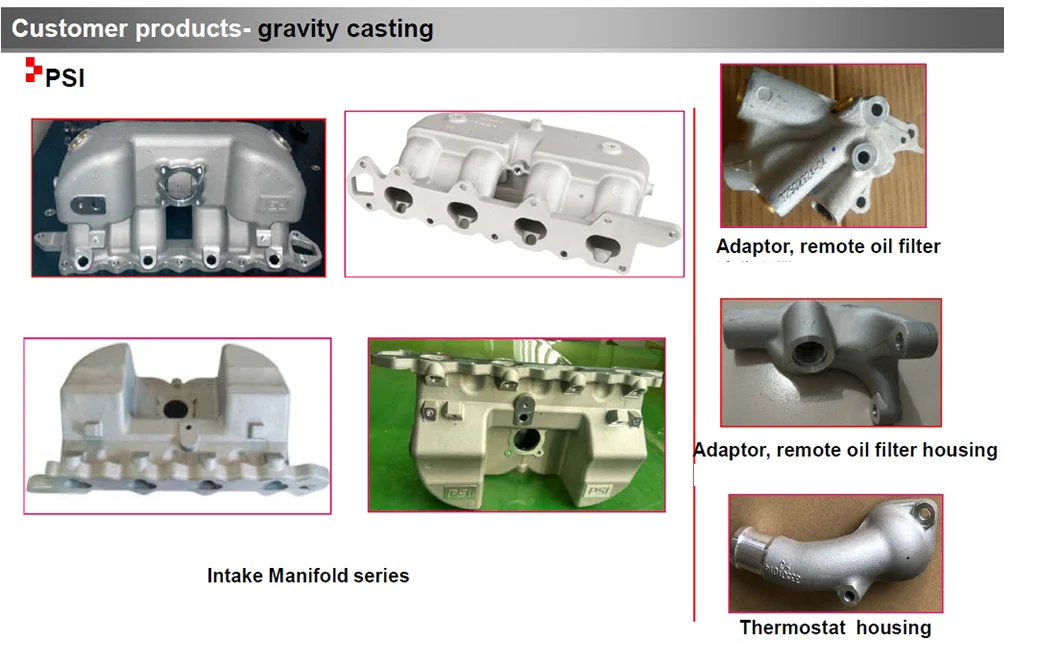

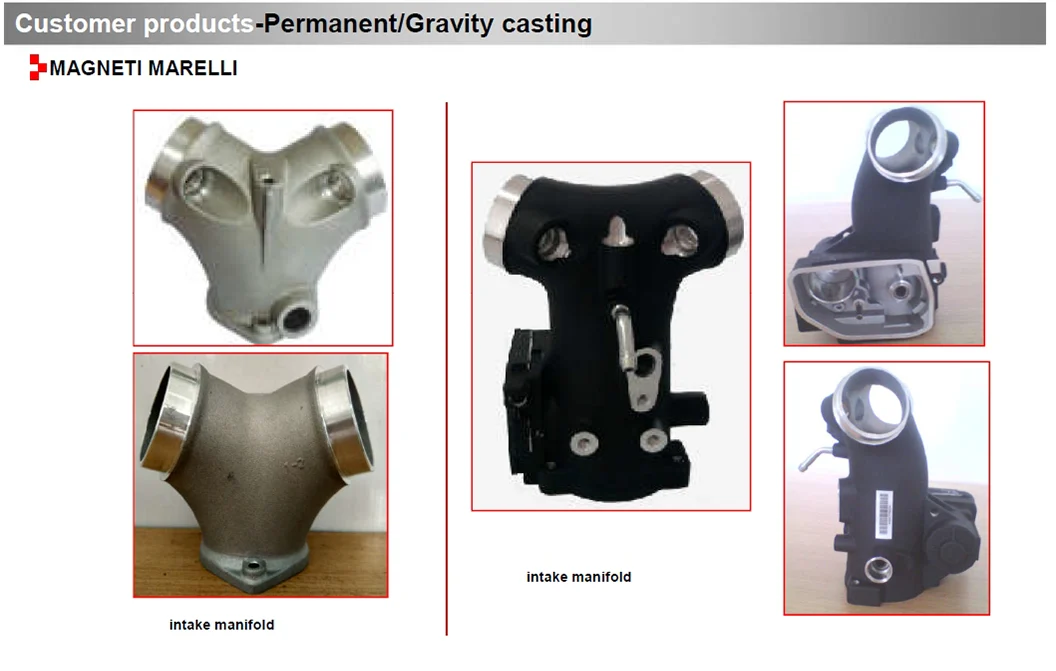

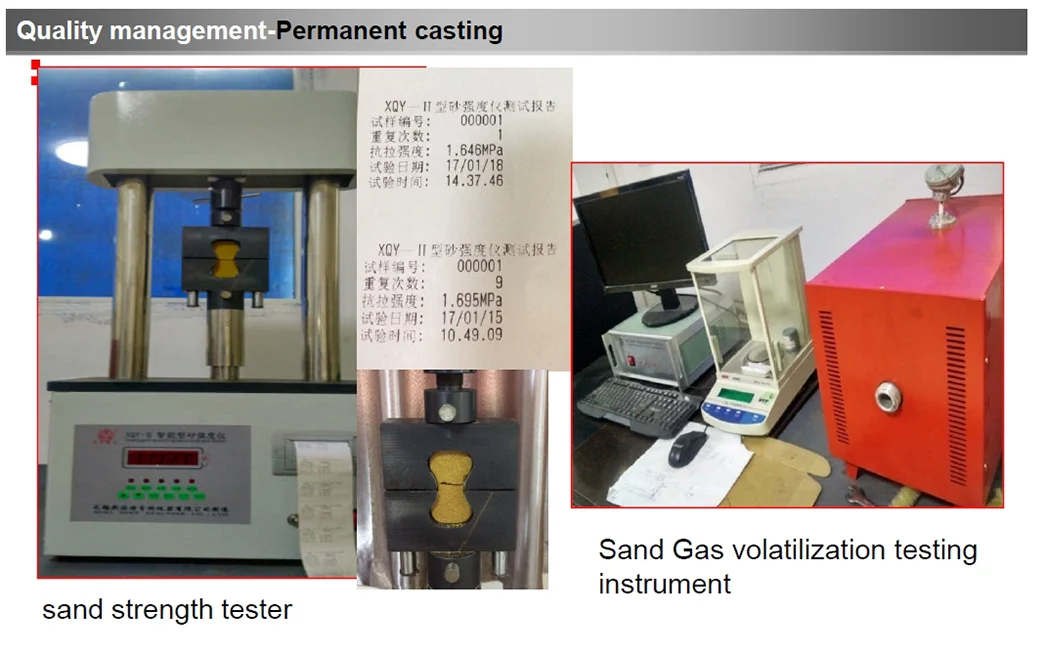

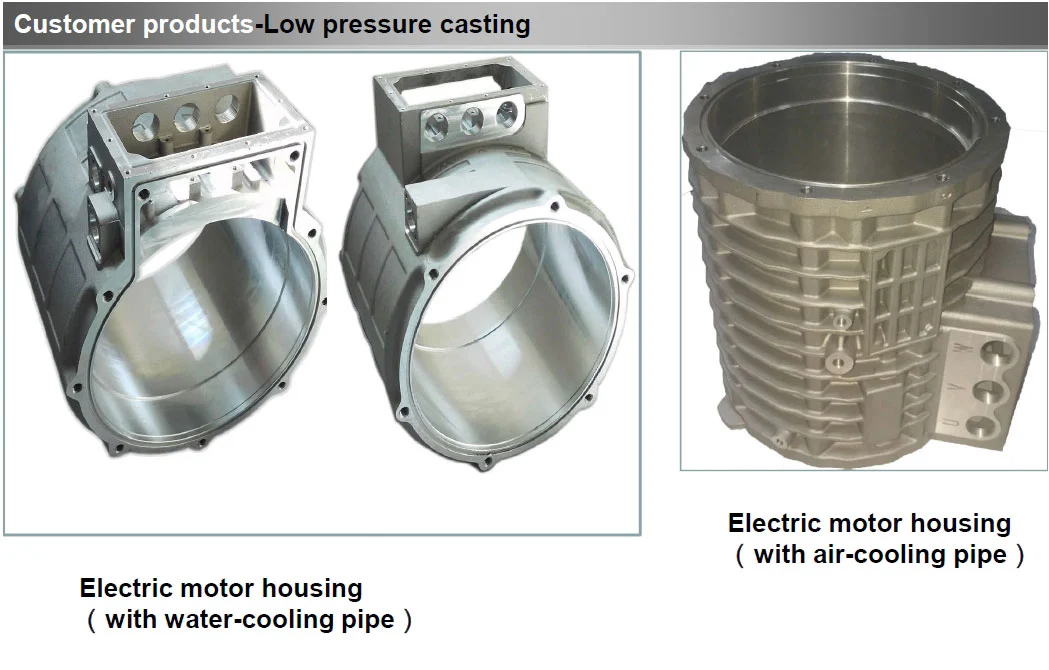

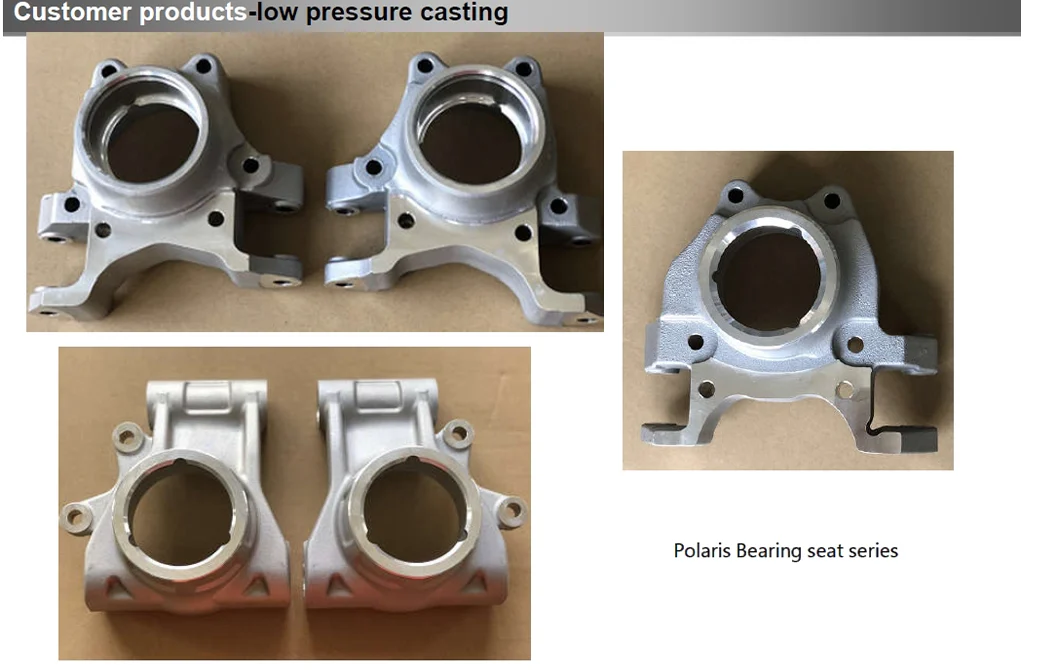

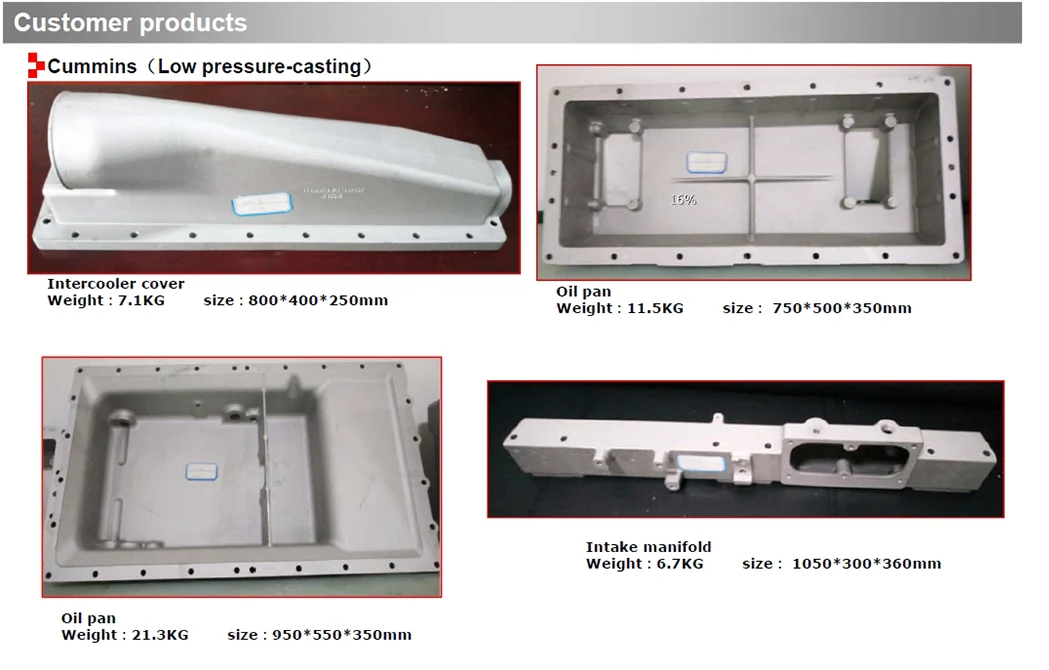

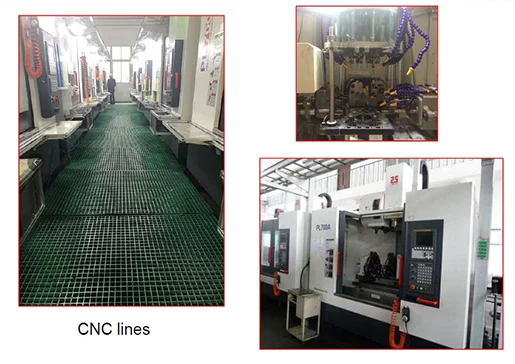

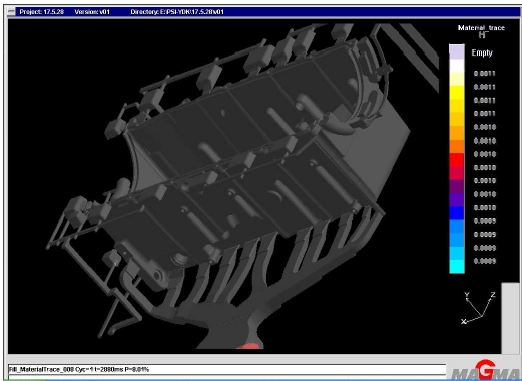

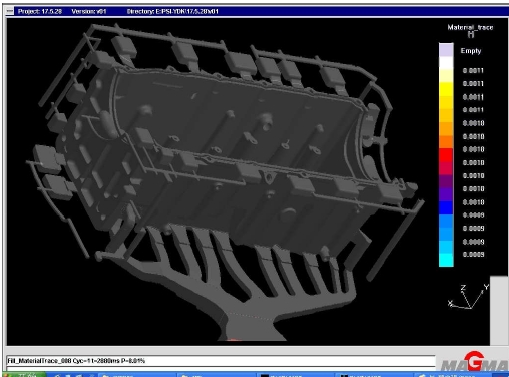

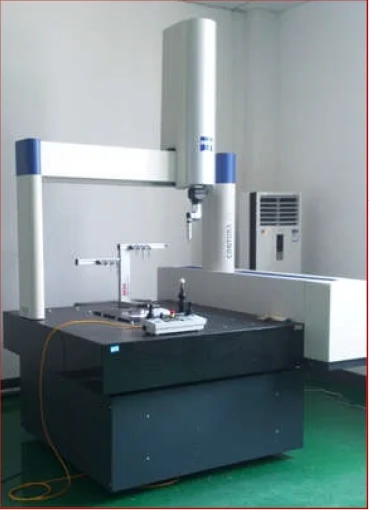

Specializing in precision aluminum die casting, sand casting, and investment casting services. We manufacture high-performance aluminum alloy castings for automotive, industrial, and aerospace applications. Our ISO-certified foundry combines advanced casting technology with strict quality control to deliver durable, lightweight aluminum components at competitive prices.

• 20+ years aluminum casting expertise

• Custom aluminum casting solutions

• Strict quality assurance (ISO 9001)

• Fast prototyping & mass production

• Global export experience

Request a quote today for your aluminum casting projects!

Get a Quote