Aerospace casting

We are a leading aerospace castings manufacturer based in China. As an aerospace investment casting enterprise, we are committed to supplying a diverse range of aerospace parts to meet the unique needs of various customers.

Aerospace casting is a specialized manufacturing process that involves the creation of precision components and parts for the aerospace industry through casting or moulding techniques. In this process, molten metal, with aluminum being the most commonly used material, is carefully poured into a mould of the desired shape. After that, the metal is allowed to solidify and cool.

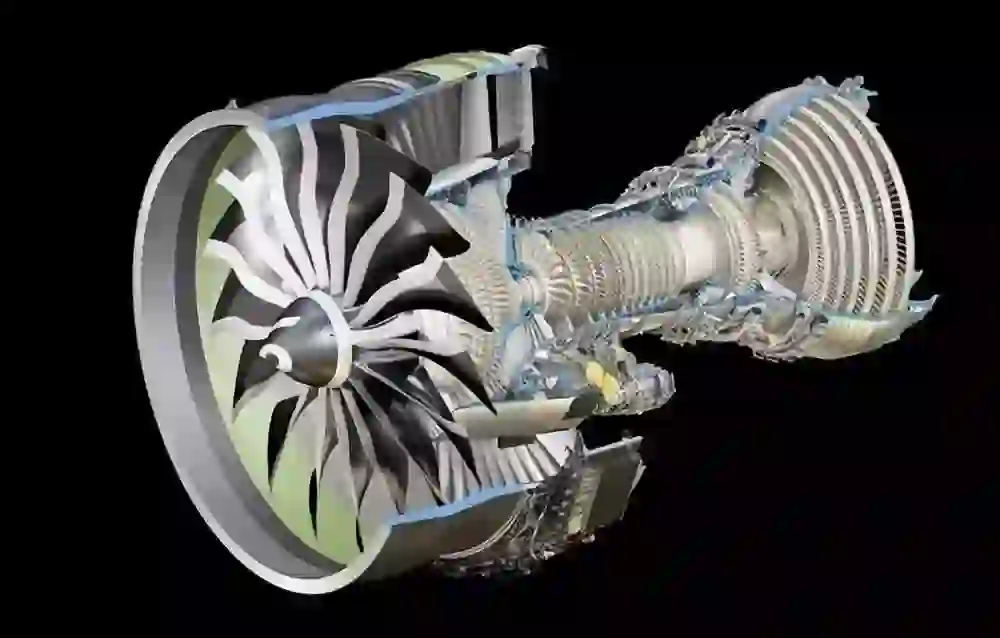

This manufacturing method plays a crucial role in the production of a wide variety of aerospace components. These include turbine engine parts, which are vital for the efficient operation of aircraft engines; airframe structures, providing the necessary strength and stability to the aircraft; landing gear, ensuring safe take – offs and landings; and control surfaces, enabling precise flight control.

Given the high – stakes nature of the aerospace industry, the aerospace casting process demands an extremely high level of accuracy and precision. Every part produced must meet the stringent quality standards that are characteristic of this industry. To achieve this, advanced technologies such as computer – aided design (CAD) and simulation software are extensively utilized in the manufacturing process. These technologies help in optimizing the design, predicting potential issues, and ensuring the highest quality of the final products.

The investment casting process is widely recognized as a cost-effective manufacturing method for producing various custom parts in the aerospace industry. This technique is particularly advantageous because it allows for the creation of castings with varying levels of complexity, all of which can be made from lightweight, durable, and corrosion-resistant materials. These materials are essential for aerospace components, as they must endure some of the most extreme operating temperatures and high-stress environments while maintaining minimal weight. As one of the leading aerospace castings manufacturers, Chongqing Sipx specializes in providing high-precision molten casting products to customers in the aerospace, UAV, and other related industries. With over a decade of experience, we have developed a profound understanding of the stringent quality and accuracy requirements necessary for both commercial and military aerospace applications.

Additionally, aerospace casting can also refer to the creation of molds for aerospace-themed crafts, which are often used as gifts or toys. As illustrated in the following picture:

What areospace parts are suitable for investment casting to make out?

Parts that can be made using investment casting in aerospace crafts include turbine blades, impellers, gears, fuel injection nozzles, compressor wheels, and structural components such as brackets, handles and housings. Investment casting is a preferred method to create complex shapes with high precision and accuracy, making it ideal for aerospace applications.

What material are usually used in aerospace casting?

Aerospace casting typically use materials such as aluminum alloys, titanium alloys, nickel alloys, and composites like carbon fiber reinforced polymer (CFRP) or glass fiber reinforced polymer (GFRP). These materials possess properties like lightweight, high strength, corrosion resistance, and thermal resistance that make them ideal for aircraft and spacecraft applications. Copper alloys, steel alloys, and magnesium alloys are also used in specific applications

Aerospace casting manufacturers

We at sipx casting are proud to say that we are experts in aerospace casting manufacturing. With extensive knowledge and experience in this field, we are committed to providing only the highest quality products to our customers. Our skilled team of engineers, designers, and technicians work tirelessly to ensure that every casting project meets the strictest industry standards and exceeds the expectations of our clients. From concept to production, we utilize the latest technology and modern manufacturing methods to achieve flawless results. Our expertise in this field has enabled us to deliver successful projects for various aerospace companies worldwide. Trust us to be your reliable partner in aerospace casting manufacturing and experience the benefits of working with our team of experts.

Precision casting process for titanium alloy components used in aerospace castings

With the increasing advancement of space vehicles such as rockets, missiles, and airplanes, higher requirements have been put forward for the mechanical properties of their key structural materials. For example, higher requirements have been put forward for specific strength and stiffness at room and high temperatures, creep resistance at high temperatures, ultimate service temperature, and high-temperature oxidation resistance. Titanium alloys and intermetallic compounds are essential high-tech new materials for the development of cutting-edge technologies in aerospace and national defense.

The precision casting process of titanium alloys and intermetallic compounds has always been one of the cutting-edge research topics for scientists. The solidification structure and precision casting process of Ti-Al-Zr high-temperature titanium alloy, which works for a long time above 500 ℃, were proposed due to the demand for precision forming of titanium alloy for a certain type of rocket engine.

(1) Test method

① Wax mold preparation. Using an American MPI wax press with a maximum clamping force of 1000kN, using WM114 wax material, the melting point of the wax material is 70-80 ℃, the operating temperature is 50-60 ℃, the shrinkage rate is 0.6% -0.8%, and the ash content is relatively low.

② Shell manufacturing. The surface layer of the shell refractory material is made of ZrO2, and the back layer is made of ethyl silicate binder. Corundum powder and sand refractory materials are used.

③ Dewaxing and shell roasting. Steam dewaxing is adopted, with a dewaxing kettle pressure of 0.4-0.6 MPa and a dewaxing time of 8-10 minutes. The roasting is carried out using a resistance furnace, with a roasting temperature of 950-1000 ℃ and a roasting time of 2 hours.

④ Alloy melting. Ti Al Zr alloy was melted in ALD water-cooled copper crucible induction melting with a melting power of 370kW, voltage of 800V, current of 900A, frequency of 5.7kHz, and working pressure of 10-2Pa.

(2) Results and Discussion

① Stability of shell dimensions. Obtaining a shell with high room temperature strength ensures the size and surface layer of the shell during dewaxing and transportation processes.

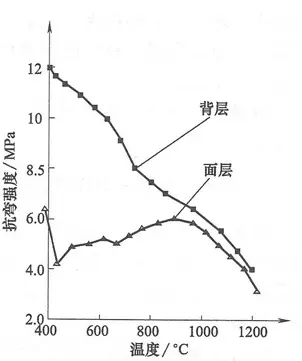

The key to not falling off. The greater the adhesive effect of the colloid in the binder, the higher the room temperature strength of the shell, reaching 4.96 MPa, which can meet the requirements of precision casting of titanium alloy Aerospace casting parts for engines. The residual strength of the surface layer shell shows a curve increase, with the lowest at 900 ℃ and the highest at 1200 ℃. The high-temperature residual value of the Aerospace casting shell is between 4.1 and 6.0 MPa. The surface layer shell has high high-temperature residual strength and can withstand the impact of molten metal. The surface layer shell is not easy to fall off, and the surface quality of the poured Aerospace casting parts is good, as shown in Figure left. The dimensional stability of the shell is an important factor affecting the dimensional accuracy of Aerospace casting, and is related to phenomena such as shell deformation, cracking, and fire during pouring.

Due to the series of physical and chemical changes that occur in the shell at high temperatures, the dimensional stability of the shell also affects the variation of the shell dimension line and the bonding between the surface layer and the back layer. The coefficient of thermal expansion can directly reflect these two changes. Figures 6-40 show the difference in thermal expansion coefficients between the surface layer and the back layer at 400 ℃. As the calcination temperature increases, the thermal expansion coefficient of the surface layer shell gradually increases. The thermal expansion coefficient of the back shell gradually decreases, with a difference of zero at 850 ℃.

Later, as the temperature continues to rise, the difference in thermal expansion coefficients between the two gradually increases, and at 1200 ℃, the difference is close to twice. Therefore, it is best not to exceed 1200 ℃ for the entire roasting temperature. Beyond this temperature, the expansion difference between the surface layer and the back layer is too large, which can easily cause layering between the surface layer and the back layer, and have an adverse effect on Aerospace casting. The thermal expansion situation is shown in Figure right.

② The microstructure of Ti-Al-Zr alloy. The characteristics of solid-state phase transformation in titanium alloys are diversity and complexity, and the vast majority of phase transformations present in metals can occur in titanium alloys. The microstructure of titanium alloy includes a structure β Different organizations, such as organization and Weinstein organization, have a significant impact on performance.

The microstructure of Ti-Al-Zr alloy in Aerospace casting parts α Xianghe β Mixed, with flakes α The orientation of the phase is multiple, the number of groups is large, and the organization is small, indicating that the Ti-Al-Zr surface layer alloy Aerospace casting parts structure is a network like Weinstein structure.

③ Mechanical properties at room temperature. After room temperature tensile testing, the room temperature tensile strength of Ti-Al-Zr alloy ingots is 1057.5MPa, yield strength is 995MPa, elongation is 18.45%, and elastic modulus is 117.4GPa. Ti-Al-Zr alloy is a near a-phase alloy with only a single-phase structure and does not have the conditions to undergo aging strengthening. The alloy is strengthened by alloying elements.

④ High temperature mechanical properties. According to the working environment requirements of the engine intake pipe, the high-temperature performance of the Ti-Al-Zr Aerospace castings was tested at a temperature of 500 ℃. The tensile strength of the Ti-Al-Zr Aerospace castings alloy at 500 ℃ was 658.7MPa, the yield strength was 538.9MPa, and the elongation was 26.5%.

The behavior of alloys at high temperatures is different from that at room temperature. The lattice static distortion that plays an important strengthening role at room temperature will rapidly weaken with the increase of temperature. Conversely, elements that can improve the bonding ability of the matrix, slow down atomic diffusion process, and promote tissue stability have a more prominent role in improving high-temperature performance.

Firstly, alloy elements that can increase the solid-state phase transition temperature of titanium alloys have a more significant effect on improving heat resistance under the same other conditions. This is because as the phase transition temperature approaches, the stability of the structure decreases, the activity of elements increases, and the alloy softens. According to this principle, the composition of heat-resistant titanium alloy Aerospace castings should be based on α Stable and neutral elements are the main elements, as for β Stable elements generally have poor effects, and only molybdenum and tungsten, which can strongly enhance the bonding ability of titanium atoms, can limited increase the high-temperature strength of the alloy within an appropriate concentration range.

Secondly, from an organizational perspective, within the concentration range of single-phase solid solutions, heat resistance increases with increasing concentration, but decreases when only the second phase can appear in the organization. This is in line with the general rule, as the multiphase structure occurs during the heating process α → β Transformation promotes atomic diffusion near the phase interface, leading to a decrease in heat resistance. Therefore, it is advisable to use single-phase structure for heat-resistant titanium alloys, which are generally used α Type or near α As a material for high-temperature operation. However, the elements and microstructure of the Ti-Al-Zr alloy tested earlier meet the above two conditions, and the high-temperature stability and mechanical properties of the Aerospace casting alloy are relatively good.

FAQ

- What is aerospace casting?

Aerospace casting is the process of creating complex metal parts through the use of specialized molds and alloy materials. These parts are used in the aerospace industry for a variety of applications such as engines, turbines, and airframe components.

- What are the types of aerospace casting?

There are several types of aerospace casting including sand casting, investment casting, permanent mold casting, and die casting. Each method has its own advantages and limitations depending on the specific needs of the part being produced.

- What materials are used in aerospace casting?

Aerospace casting involves the use of high-performance alloys such as titanium, aluminum, and magnesium. These materials offer excellent strength, durability, and resistance to corrosion, making them ideal for use in aircraft components.

- What is the process of aerospace casting?

The process of aerospace casting involves several steps including mold preparation, melting and pouring of the alloy material, cooling and solidifying of the part, and post-casting finishing and inspection. Each step is carefully controlled to ensure high-quality parts are produced.

- What are the benefits of aerospace casting?

Aerospace casting offers several benefits over other manufacturing methods including the ability to create complex geometries, excellent mechanical properties, high production efficiency, and cost-effectiveness.

- What are the challenges in aerospace casting?

Aerospace casting is a complex process that requires high levels of skill and expertise. Some of the challenges include ensuring material purity, preventing defects and porosity, and achieving tight tolerances for critical components.

- What is the role of computer simulation in aerospace casting?

Computer simulation is used to simulate the casting process and predict the flow behavior of the molten metal inside the mold. This information is used to optimize the casting process and reduce the risk of defects in the final part.

- How is aerospace casting quality controlled?

Aerospace casting quality is controlled through a variety of methods including visual inspection, non-destructive testing, and computerized tomography. These methods help to identify and address any defects or issues that may arise during the casting process.

- What are the applications of aerospace casting?

Aerospace casting is used in a wide range of applications in the aerospace industry including engine and turbine components, airframe parts, landing gear components, and more.

- How important is aerospace casting in the aerospace industry?

Aerospace casting is a critical part of the aerospace industry, providing high-quality, durable parts that are essential for the safe and efficient operation of aircraft. As the demand for more advanced aircraft continues to grow, the importance of aerospace casting will only continue to increase.